Stellantis Battery Packs Getting a Massive Upgrade

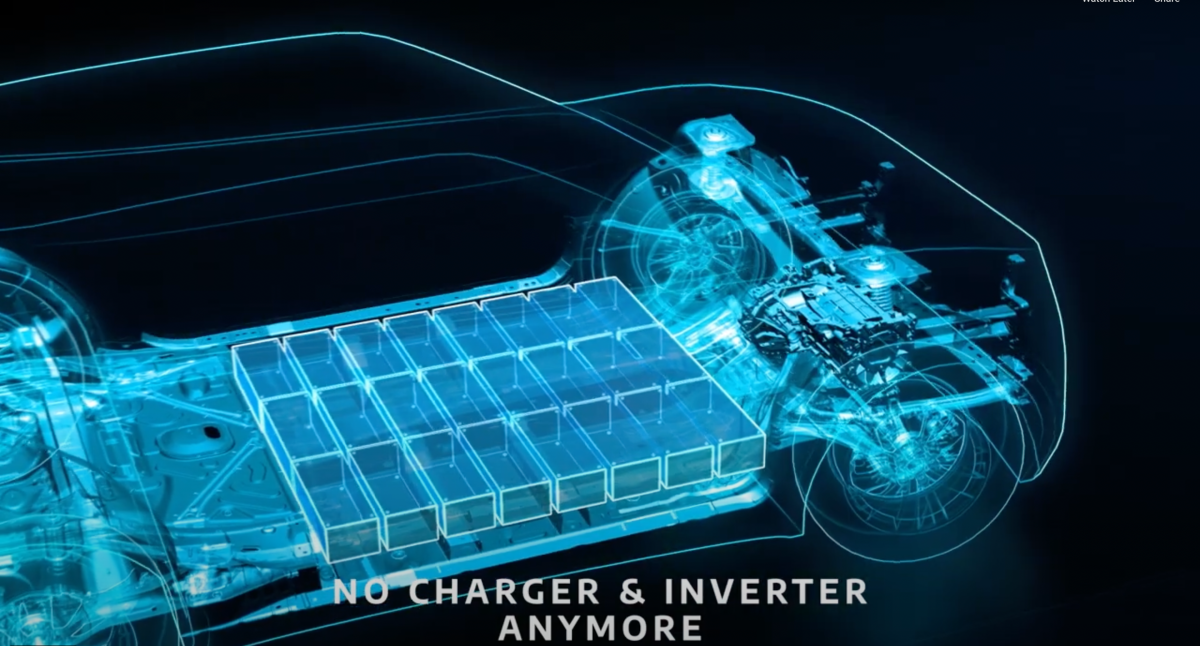

Stellantis is successfully testing a revolutionary approach to electric vehicle battery design that could reshape its EV architecture. The Intelligent Battery Integrated System (IBIS) integrates the inverter and charger functions directly into battery modules, eliminating the need for separate charging hardware that typically adds weight and complexity to electric vehicles.

The IBIS system uses software control to manage these integrated functions, reducing vehicle weight by 88 lbs on average, freeing up space and reducing charging time by 15%. The innovative battery technology is also 10% more efficient than conventional EV systems with the same-sized battery pack, potentially extending range without increasing battery capacity. Each battery module operates independently through sophisticated software, creating a more flexible and responsive power management system.

Stellantis

Game-Changing Benefits for Stellantis Brands

The integrated battery system represents a significant advancement in EV technology that could benefit multiple Stellantis brands across North America. Jeep's current 4xe lineup, including the Grand Cherokee 4xe with its 26-mile electric range and Wrangler 4xe offering 21 miles of electric-only driving, could see meaningful improvements with IBIS technology implementation.

A 10% efficiency boost would translate to approximately 2.6 additional miles of electric range for the Grand Cherokee 4xe and over 2 miles for the Wrangler 4xe. While these gains might seem modest, they represent meaningful improvements where every mile of electric range reduces reliance on gasoline. The weight reduction of 88 pounds also improves overall efficiency. Dodge's Charger EVs could also benefit from up to 30 miles of additional range and space savings, while Ram's recently shelved electric pickup truck could have leveraged the faster charging capabilities and reduced complexity.

Too Little, Too Late?

Traditional EVs use separate onboard chargers that convert grid AC power to DC for battery storage, while onboard inverters convert battery DC power to AC for electric motors. By consolidating these functions into the battery pack itself, Stellantis creates opportunities for simplified vehicle assembly, reduced manufacturing costs, and improved reliability. The technology also improves Stellantis' position against Tesla and Ford in the rapidly evolving EV market.

The IBIS technology could prove valuable as Stellantis accelerates its electrification timeline across brands like Dodge, which plans to transition its performance lineup to electric power. The system's ability to provide faster charging and higher efficiency while maintaining smaller packaging requirements addresses two critical consumer concerns about EV adoption. Stellantis says the technology should see production before 2030, but really, it can’t come soon enough.

from Autoblog News https://ift.tt/CeM0Rpd

0 Comments